What are Fuel Injectors and what are their use?

Fuel injection systems may vary, but their purposes are always the same:

- Produce energy

- Efficient fuel combustion

- Reduce polluting emissions

- Facilitate smooth driving and engine reliability

- Diagnostic capability

Modern digital electronic fuel injection systems achieve these goals more efficiently and consistently than previous fuel systems. Also, they are able to better atomize the fuel.

Fuel injection provides smoother and more consistent throttle response, quick throttle reaction times, easier cold starting, accurate adjustment of fuel taking in to account the changes in ambient temperatures and air pressure, more stable idling with the main aim of reducing overall vehicle emissions. Therefor, fuel injectors are vital parts of every fuel system. It is important to maintain them. How does an injector cleaner improve the performance of vehicles?

Gasoline / Petrol Direct Injection

In a direct injection engine, fuel is injected directly to the combustion chamber as opposed to injection before the intake valve.

Due to their location the injectors are exposed to more heat and pressure. Costly materials and higher-precision electronic management systems are required. Direct injection offers alternative methods in fuel distribution with wall guided, spray guided and air guide applications using different manifold and piston configurations and intricately shaped injector nozzles to direct the fuel and air mixture to the point of ignition improving combustion efficiency.

Diesel Engines: Common Rail

Modern diesel engines use common rail or unit injector direct injection systems with now the introduction of Piezo injectors. These systems closely monitor and adjust the fuel delivery to maintain performance and emissions values.

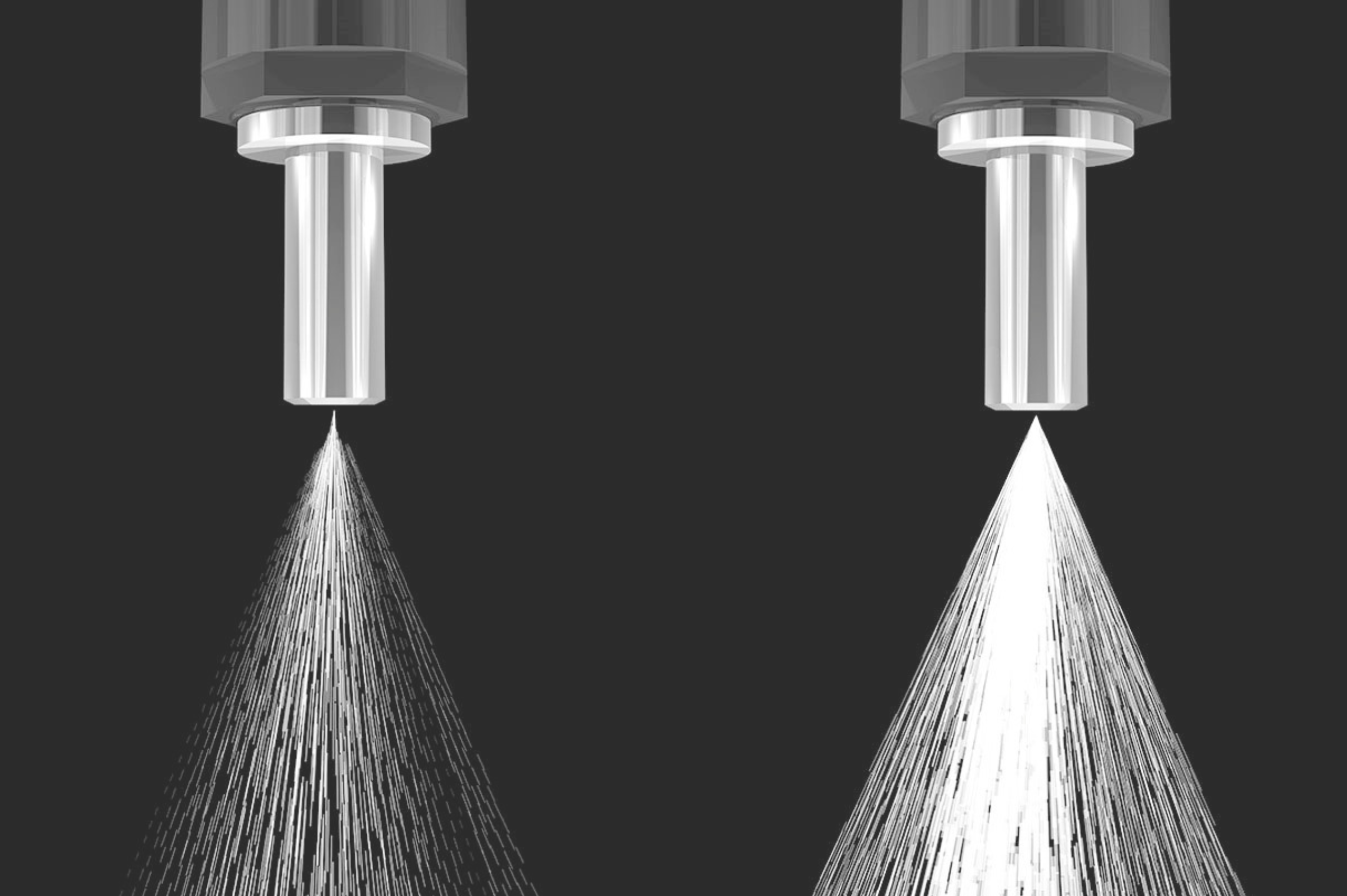

Diesel or Gasoline / Petrol engines: Multi-Hole Injectors

Both diesel and petrol injection systems now incorporate multi-hole injectors giving finer distribution of fuel within the combustion chamber to promote clean and efficient combustion. Holes the size of a human hair are shaped and cut to disrupt the fuel and enhance the spray pattern.

Fuel injectors are very sensitive components are care must be taken when removing or refitting and when replacing a new injector this must be conducted in a clean environment. Any dirt to the injector during fitting can result in damage to the component in its early days of operation.

Why use an Injector Cleaner?

With tight tolerances within the injectors and the location close or inside the combustion chamber, small amounts of contamination can have a dramatic effect on the operation and fuel distribution.

Poor injector spray patterns lead to incomplete combustion. This will increase contamination build-up in other areas of the engine including oil system, intake system and EGR, turbo, catalyst and DPF/GPF (Diesel Particulate Filter/ Gasoline Particulate Filter). One of the impacts is the reduction in exhaust gas temperature when incomplete combustion occurs. Exhaust gas after treatment systems rely on temperature to operate correctly to maintain emissions and reduce particulates from the exhaust.

What should you know about Injector Cleaners?

Keeping the fuel injectors clean will maintain engine performance and reduce component related contamination faults or breakdowns. Clean injectors will also provide fuel efficiency and keep emissions low. Where a fault is present, direct cleaning of the injectors can rectify the fault or assist in the diagnosis of a faulty injector. Dirty injectors affect the whole combustion process and this can lead to further problems. Increased emission will build up in the EGR (Exhaust Gas Recirculation) system, affect the performance of diesel and gasoline particulate filters, contaminate the oil system reducing its protective performance increasing engine wear.

Why are Injector Cleaners effective? What characteristics should I take into account?

Cleaning the injectors can be a simple solution with the addition off an additive to the fuel tank and driving the vehicle as normal. It is however to select an additive suitable for the system and an additive of quality which can withstand and survive the pressures and temperatures at which the fuel injector operate at. Only when these elements are correct, a driver will gain the maximum benefit from cleaning the injectors.

These benefits range from an improved fuel economy, better performance and vehicle response, lower emissions and reduced contamination impact of other vehicle components such as the engine oil, catalytic converters and particulate filters. The driver should feel improved vehicle response, smoother running and better starting.

The fuel injector is the key component for fuel distribution to the engine. Keeping the injectors clean is a vital part of maintaining vehicles. Done regularly, it will help to maintain your vehicle and reduce component problems. In the end, this will save the driver money.

Leave A Comment